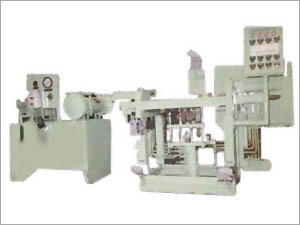

Gravity Die Casting Machine

Product Details:

X

Product Description

MOVEMENTS: The following movements are provided on the machine.

Mould: Two mould halves are having two independent movements. Each has a travel of 250 mm. The maximum distance between two halves is 500 mm. The two halves are guided and held down on the bed on hardened guide ways. The maximum die surface available at the parting plane is 400 mm length and 350mm height. The maximum die thickness can be 150 mm. Ejector plate design can be provided on either or both the halves. Shell core placing is manual and the die must have suitable design for the purpose.

Top Core: The minimum and maximum distance between the top core provided and the bed surface is 300 mm and 600 mm.

Bottom Core: The minimum and maximum distance between the bottom core provided and the bed surface is 0 mm and 80 mm.

Rear Core: Rear core is also provided with a travel of 100 mm.

Tilting: The main bed carrying the die tilts up and down during the automatic cycle. The speed of movement is adjustable independently in both the directions. The angle of tilting also is adjustable between 0o and 45o.

HYDRAULICS: The machine is supplied with a hydraulic power pack of 250 litres tank, 7.5 HP motor, a gear pump 45 LPM, relief valve, heat exchanger etc. complete in all respects. All movements are given by hydraulic cylinders operated by solenoid controlled valves.

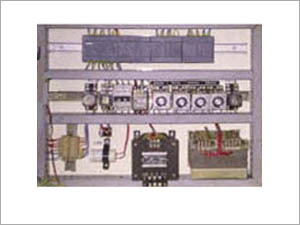

CONTROLS AND AUTOMATION: The machine works semi-automatically. Shell core placing, metal pouring and picking up the casting are manual. Complete cylinder/die movements, cooling of various areas, cycle time etc. are automatic. In manual operation each cylinder can be operated manually and independently as well. Selector switches are provided to include or delete top core, rear core and bottom core depending on the requirements of the particular component to be cast. Two nos. of solenoid controlled water cooling valves are provided for die cooling. The duration of cooling is adjustable through electronic timers. We are using SIEMENS S7-200 series PLC in the machine for all controls and automation

Mould: Two mould halves are having two independent movements. Each has a travel of 250 mm. The maximum distance between two halves is 500 mm. The two halves are guided and held down on the bed on hardened guide ways. The maximum die surface available at the parting plane is 400 mm length and 350mm height. The maximum die thickness can be 150 mm. Ejector plate design can be provided on either or both the halves. Shell core placing is manual and the die must have suitable design for the purpose.

Top Core: The minimum and maximum distance between the top core provided and the bed surface is 300 mm and 600 mm.

Bottom Core: The minimum and maximum distance between the bottom core provided and the bed surface is 0 mm and 80 mm.

Rear Core: Rear core is also provided with a travel of 100 mm.

Tilting: The main bed carrying the die tilts up and down during the automatic cycle. The speed of movement is adjustable independently in both the directions. The angle of tilting also is adjustable between 0o and 45o.

HYDRAULICS: The machine is supplied with a hydraulic power pack of 250 litres tank, 7.5 HP motor, a gear pump 45 LPM, relief valve, heat exchanger etc. complete in all respects. All movements are given by hydraulic cylinders operated by solenoid controlled valves.

CONTROLS AND AUTOMATION: The machine works semi-automatically. Shell core placing, metal pouring and picking up the casting are manual. Complete cylinder/die movements, cooling of various areas, cycle time etc. are automatic. In manual operation each cylinder can be operated manually and independently as well. Selector switches are provided to include or delete top core, rear core and bottom core depending on the requirements of the particular component to be cast. Two nos. of solenoid controlled water cooling valves are provided for die cooling. The duration of cooling is adjustable through electronic timers. We are using SIEMENS S7-200 series PLC in the machine for all controls and automation

Other Products in 'Piston Die Casting Machine' category

Contact Details

TECHNO MACHINES

Chikkanahalli Road, Opp. Shahi Exports (Unit No 6), Near Annapoorneshwari Temple, Bommanahalli,Bengaluru - 560068, Karnataka, India

Key Personnel

Mr. Jagadish Kumar G.P.

(Proprietor)

|

|

|

|

TECHNO MACHINES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |